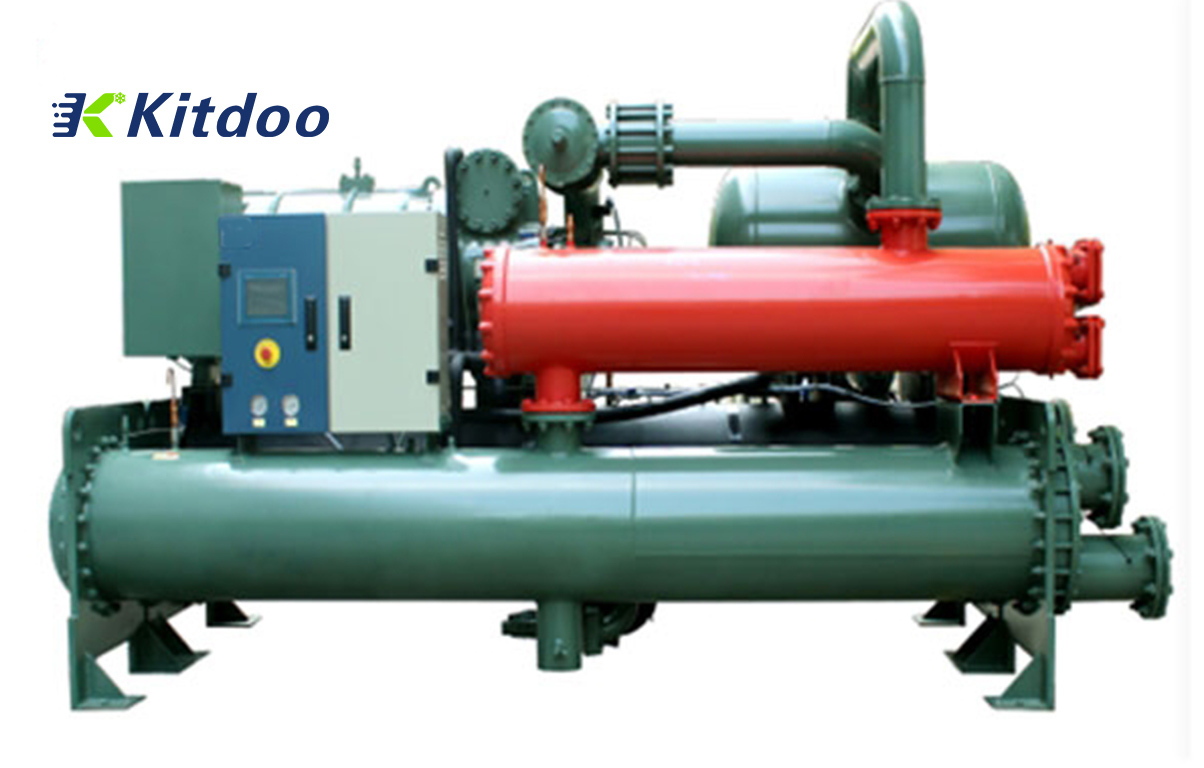

Screw type water cooled chillers are mainly composed of a semi hermetic twin screw compressor, a water cooled condenser, a flooded evaporator, an oil separator, a throttling mechanism, and an electrical control system.

The refrigerant gas evaporated in the evaporator is continuously sent to the condenser to maintain the high and low pressure difference of the system.

(4) Oil separator:

The refrigerating oil discharged with the refrigerant gas is separated and directly sent back to the compressor to ensure the safe and reliable operation of the compressor.

(5) Electronic control system:

Using PLC or single-chip control system, the output cooling capacity of the unit can be automatically adjusted to meet the actual needs of the user; it can control the user side, the heat source measuring pump and the cooling tower fan; display the following parameters: chilled water inlet and outlet temperature, cooling water inlet and outlet temperature, evaporation, System parameters such as condensing pressure; current faults and historical fault records can be inquired.

2. Introduction of refrigeration system

The water-cooled screw chiller is a type of vapor compression refrigeration unit. The principle of refrigeration is to use the compressor to apply energy to the refrigerant vapor to increase its pressure and temperature, and then through the process of condensation and throttling to make it low pressure. The low-temperature refrigerant liquid evaporates into vapor in the evaporator, and at the same time The surrounding environment (refrigerant, such as cold water) gains heat to reduce the temperature of the refrigerant, thereby achieving the purpose of artificial refrigeration. It can be seen that the vapor compression refrigeration cycle includes four essential processes such as compression, condensation, throttling, and evaporation.