Note: The liquid level in the liquid storage tank should be between 1/3~2/3, and the filling of refrigerant cannot be lower than or exceed this standard.

2. Sight glass

Function: Display the refrigeration flow and water content.

Precautions:

a. The sight glass on the liquid supply pipeline is filled with no air;

b. When the indicator color of the sight glass is green, it means that the water content of the system is required. When the indicator is yellow, it means that the water content of the system has exceeded the standard. The water content of the system should be reduced by invalidating the filter dryer.

3. Oil separator

Function:Oil separator can separates the refrigerating oil in the high temperature and high pressure gas discharged from the compressor to prevent the refrigerating oil from entering the system and affecting the refrigeration effect.

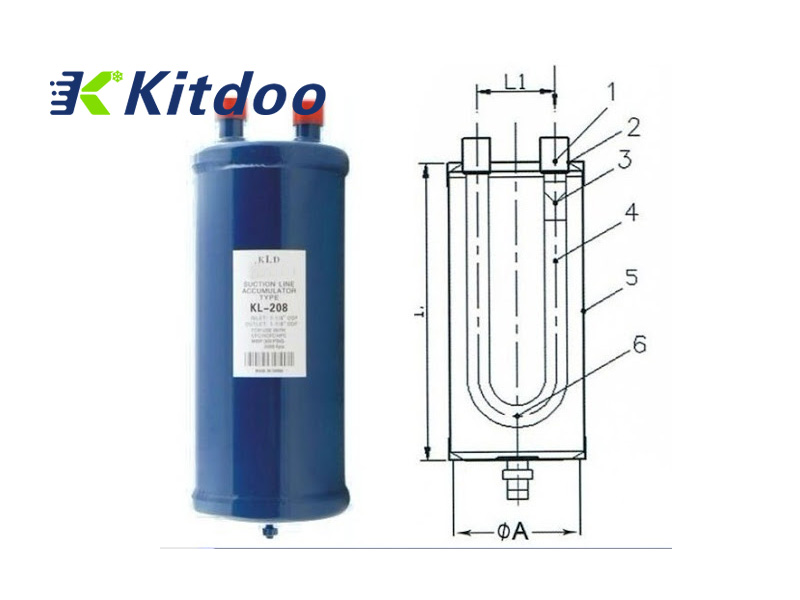

4. Gas-liquid separator

Function: The liquid refrigeration that may be contained in the low temperature and low pressure gas returned from the evaporator is intercepted to prevent the liquid refrigerant from entering the compressor and causing liquid shock.

Note: The same as the return air pipe, it should be wrapped with an insulating layer.

5. Filter

Classification: Return air filter, liquid supply drier filter, oil filter

Function: Filter impurities in refrigerant or refrigerating oil.

Note: When there are many impurities in the system, the filter should be replaced.

6. Anti-vibration tube

Function: The compressor spring tube requires flexible metal hoses (shock absorbers) to be installed on the suction and exhaust pipes to prevent the compressor from transmitting vibration and noise through the refrigerant pipeline, absorb the vibration generated by the compressor, and protect the entire pipe Road system.

Note: The shock absorber tube should be as parallel to the crankshaft as possible. In the starting phase, the starting torque of the motor makes the compressor swing to both sides, and the shock absorber tube installed parallel to the crankshaft is easy to adapt to this movement. The shock absorber tube installed horizontally is not allowed to be perpendicular to the crankshaft.